Does your lumber make the grade?

Woodchips

A newsletter from the Area 515 Makerspace Woodshop.

Measurement of Hardwood lumber and the grading of common constuction (yard) lumber.

by Jason Bentley

How much lumber do I get for 4 board feet? What are the grades of lumber, and why is grade B better than grade 1? Oh, and the most important question, why do we even care? These questions and more will be answered.

Measurement

First, let’s take a short look at how hardwood lumber is sold. The most common measurement is the board foot. This is 12” wide by 12” long and 1” thick as sold. So, 1 board foot is 144 cubic inches which makes a board 6” wide 8’ long and 3” thick is 12 board feet of lumber.

6 X (8 X 12) X 3 = 1728 / 144 = 12 board ft.

Very special pieces of lumber such as knife scales, pen blanks, lutherie (musical instrument) woods may be priced by the linear foot, linear inch, square inch, or by the piece. I have paid upwards of $6.00 per square inch for fine veneer.

Grading

Now that you have a rough idea of how lumber is measured next let’s look at how lumber is graded. Unfortunately, there are many grading systems used for lumber some of which are proprietary, new, or just not in common use. Those will not be covered here. I will attempt to illuminate the standard yard or construction grades of lumber.

Most woodworkers start with common yard lumber from their favorite big box store so we will start with this. Lumber in this category is graded Select A through D, and Common 1 through 5.

Select grades also commonly know as paint grade lumber these are some of your best yard grade lumber and while pretty are not graded for construction load bearing qualities.

A Does not exhibit knots, splits, or visible defects. Better quality door, window, and home trim.

B Few small visible defects. Used for some painted cabinets and door and window trim.

C Small knots, but one side may be completely clear of defects. Commonly used for trim in homes.

D May contain pin knots and small blemishes.

Common grades are numbered and are:

1 Construction Moderate small defects and tight knots. Paints well. Used for paneling, siding, and shelving.

2 Standard Larger and more numerous tight knots. Paints fairly well same uses as #1.

3 Utility Contains splits and loose knots. Will not paint well. Used for subflooring, sheathing, crates and pallets.

4 Economy Numerous splits, knot holes, and defect. Will not paint well. Used for subflooring, and sheathing. Not suitable for pallets or crating.

5 Dunnage Commonly used for backing material, padding, and anything that does not have to be structurally sound. I call it kindling.

So, what about STUD or BEAM? Stud is a subset of structural lumber as below.

Structural lumber is classified into seven categories:

1. Light Framing. Lumber that’s 2 to 4 inches thick and up to 4 inches wide. Graded as either Construction, Standard, or Utility. Here’s what those designations mean.

Construction. Small, tight knots and knotholes permitted with guidelines.

Utility. Splits allowed that are equal to 1/6 the width of the piece. Knots are not restricted as to quality and are permitted in greater size.

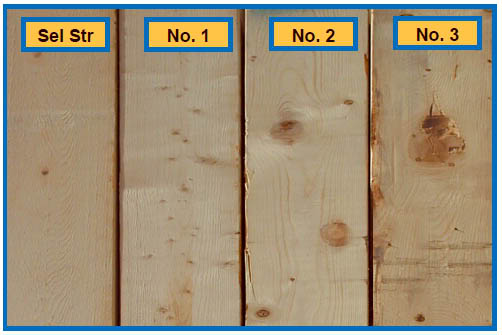

2. Structural Light Framing. Lumber that’s 2 to 4 inches thick, 2 to 4 inches wide. Graded as Select Structural, 1, 2, or 3. Here’s what those designations mean:

Select Structural. Pretty much clear of knots. The knots that do exist are small and tight. Strongest of the four grades.

No. 1. Small, tight knots up to 1-1/2” allowed. Loose knots can only be 1” wide and can only appear once every 3 feet.

No. 2. Well-spaced knots of any quality up to 2” wide. Can have knotholes that are 1-1/4” wide every 2 feet.

No. 3. Knots of any quality can be up to 2-1/2” wide. Knotholes allowed every 1-3/4” foot.

3. Studs. Lumber that’s 2 to 4 inches thick, 2 to 4 inches wide. Graded as Stud.

4. Structural Joists and Planks. Lumber that’s 2 to 4 inches thick, 6 inches and wider. Graded as Select Structural, 1, 2, or 3.

5. Beams and Stringers. Lumber that’s 5 inches or thicker with a width more than 2 inches greater than the thickness. Graded as Select Structural, 1, or 2, with Select Structural being the strongest.

6. Posts and Timbers. Lumber that’s at least 5 inches by 5 inches. Graded as Select Structural, 1, or 2.

7. Appearance Framing. Broad category of structural lumber that’s at least 1 inch thick and 2 inches wide. Aesthetics govern the grading of appearance framing. The highest grades are clear or nearly clear of any knots or blemishes. Appearance framing lumber is used in paneling and siding.There are two primary grades of appearance framing: Finish and Select. Finish grade is higher quality than Select.

Finish grading is only available in lumber from Douglass Firs and Hem-Firs. The grades are Supreme, Choice, and Quality.

Select grading applies to all Western softwood species. The grades are A, B, C, and D:

A Select. No knots, splits, or other visible defects. Used for fine furniture, exposed cabinetry, trim, and flooring.

B Select. A few, small defects but nearly perfect. Used for exposed cabinetry, trim, and flooring.

C Select. Small tight knots. Can be used for shelving and some trim and flooring.

D Select. Numerous “pin” knots and other small blemishes.

Photo by: Brett • March 4, 2015 • Last updated: October 14, 2020

Closing

You may think I repeated myself in the grading of construction grade and common softwood lumber. I did, but only because the grading repeats itself among those common grades. The lines get blurred between what is structural and what is appearance lumber at times, but the most important thing to remember is what the letter and number determine. A is your best for appearance, 1 is your best for construction, and 5 makes a great fire starter.

Next post we will examine sheet goods (plywood) and hardwood grading which is slightly simpler.

Jason Bentley

Area515 Makerspace Woodshop Steward

10/17/2020

Resources for the above article.

Recommended website:

Recommended YouTube channel:

Rex Krueger